New cutting-edge technology at White Mountains Community College enhances learning in industrial mechanics, with potential for healthcare and other curriculum

From old school to new tools, White Mountains Community College (WMCC) is changing the way students in the college’s industrial mechanics program are learning the profession. Using COVID-19 funds, WMCC was able to purchase a Hololens 2 mixed reality device and the FIXTURLASER ECO laser alignment system , bringing new augmented reality tools to its classrooms and labs. These purchases enable the college to train students within COVID-19 safety protocols, while also introducing more futuristic learning components into the curriculum, including through enhanced experiential learning.

From old school to new tools, White Mountains Community College (WMCC) is changing the way students in the college’s industrial mechanics program are learning the profession. Using COVID-19 funds, WMCC was able to purchase a Hololens 2 mixed reality device and the FIXTURLASER ECO laser alignment system , bringing new augmented reality tools to its classrooms and labs. These purchases enable the college to train students within COVID-19 safety protocols, while also introducing more futuristic learning components into the curriculum, including through enhanced experiential learning.

“Teaching people hands-on trades-related skills online has its challenges but with these new technologies, we are able to make detailed demonstrations with our students virtually in ways we never have before,” said Kyle Aubut, associate professor of industrial mechanics.

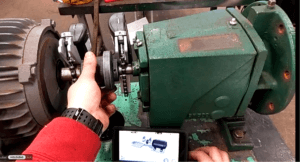

The college now owns two FIXTURLASER devices that will supplement legacy equipment to provide more precision in a variety of industrial mechanics products. The device has a Bluetooth feature and app that links directly to smartphones. The Hololens is a next generation augmented reality headset from Microsoft that enables faculty to create and share virtual reality demonstrations through video-capture technology.

The college now owns two FIXTURLASER devices that will supplement legacy equipment to provide more precision in a variety of industrial mechanics products. The device has a Bluetooth feature and app that links directly to smartphones. The Hololens is a next generation augmented reality headset from Microsoft that enables faculty to create and share virtual reality demonstrations through video-capture technology.

“Having these laser alignment tools moves us from more of an “old school” method of shaft alignment into new technology providing more consistent and accurate readouts. We will still introduce and teach dial indicator methods, so students stay familiar with both alignment methods. These new systems will also allow for smaller groups to socially distance and are easier to sanitize as the chemicals can be too harsh on the older tools,” said Aubut.

While applications for the FIXTURLASER devices are very specific, applications for the Hololens 2 are wide-ranging. Aubut sees applications going beyond industrial mechanics and into health sciences and several other fields. As a Microsoft product, it can be integrated into Microsoft Teams and easily shared with groups of students. This would allow for sharing virtual 3-D views of a whole skeleton and muscular system that can manipulated and further explored through hand motions that can turn, enlarge or shrink objects.

Aubut, who is a WMCC alumnus, also sees the two coming together in some applications. “Let’s say we were in a mechanical systems class where we’re using laser alignment tools. If a student had the Hololens on, I could walk them through step by step and tell them how to hook up the alignment device and calibrate it and run diagnostics. For video, I can record myself doing a demonstration, then share it and while using the Hololens, address questions in real time but through remote learning,” he said.

He sees additional applications in the diesel program. With the Hololens, he can work with his contacts in the industry, such as Milton CAT to show equipment used at the facility, pointing to specific machine components in real time while instructing students through Microsoft Teams. Before having the Hololens, Aubut would use his personal GoPro attached to his hard hat, go into the facility and take video.

These new tools are being incorporated into classes in the one-year Industrial Mechanics Certificate program, and Aubut expects that additional uses will arise as they explore more apps for the Hololens 2. Learn more about the industrial mechanics programs online. For more information, contact Kyle Aubut at [email protected] or 603-342-3079.